With the rapid development of emerging industries such as next-generation information technology, new energy sources, and smart manufacturing, society’s demand for quality materials has also increased. For this reason, the University of Macau (UM) has established the Macao Centre for Research and Development in Advanced Materials, whose mission is to foster technological innovation and the commercialisation of advanced materials, and to emphasise green practices, low carbon, refinement, and efficiency in Macao’s advanced materials industry.

Laying the Foundation for R&D Advancement

The new wave of technological and industrial revolution has led to unprecedented innovation in science and technology worldwide. Meanwhile, advanced materials with superior performance have become essential to the development of high-tech industries, smart cities, and urban infrastructure in Macao and mainland China. Advanced materials are developed using cutting-edge technologies and most exhibit characteristics such as high performance, high durability, low defect rates, low cost, and multi-functionality. They not only lay the groundwork for the transformation and upgrading of all industries but also serve as a cornerstone of sustainable urban development. Therefore, related research and development (R&D) work holds immense significance.

Advanced materials have long been at the heart of UM’s research layout. In 2014, the university established the Institute of Applied Physics and Materials Engineering (IAPME). The institute brings together innovative scholars from world-renowned universities and research institutes in the United States, Europe, Japan, Singapore, and Hong Kong to form a strong interdisciplinary team. Building on quantum mechanics, atomic theory, and solid-state physics, the team is committed to developing key technologies for advanced materials. After nearly a decade of concerted efforts, IAPME has fostered a thriving research environment and achieved a wealth of remarkable results. Furthermore, with the support of the Science and Technology Development Fund of Macao, UM has established the Macao Centre for Research and Development in Advanced Materials (the centre), which is the second platform for the commercialisation of industry-academia research results in Macao, after the university’s Macao Centre for Research and Development in Chinese Medicine. The centre aims to provide a conducive environment for interdisciplinary research on advanced materials, such as the next generation of semiconductors and quantum biomedical technology.

The centre is located in Research Building N23 of UM’s Research Base, adjacent to the university’s state key laboratories. Across a wall behind the Research Base is the Hengqin-Macao Youth Entrepreneurship Valley. The centre is working closely with the Zhuhai UM Science & Technology Research Institute, leveraging the opportunities presented by technological R&D and the development of the high-end manufacturing industry in Hengqin. They aim to accelerate the commercialisation of IAPME’s research results, thereby supporting the Macao Special Administrative Region to explore a market-oriented development model that organically integrates industry and academia.

Prioritising the Development of Advanced Materials

The energy crisis, environmental pollution, and global health are pressing concerns, and the IAPME research team is working on these issues. Prof Shuji Nakamura, who received the Doctor of Science honoris causa degree from UM in 2020 and the 2014 Nobel Prize in Physics, is a pioneer of sustainable energy technology. His inventions have not only revolutionised the lighting industry, but have also made significant contributions to human well-being. He recognises UM’s research direction in advanced materials. He also noted that apart from helping companies enhance their competitiveness and explore new markets, the development of advanced materials may improve productivity and the everyday living environment, ultimately benefiting society by enhancing people’s sense of well-being.

To this end, the centre integrates fundamental research with advanced materials, fosters the development of advanced materials to meet market demands, and connects with businesses to accelerate the commercialisation of research results. Prof Tang Zikang, director of IAPME and director of the centre, is an internationally renowned scholar and pioneer in the field of nano-optoelectronic materials. Over the years, he has led his team to conduct cutting-edge research on advanced materials and develop innovative techniques to tackle technological bottlenecks in the field.

According to Prof Tang, ‘Our goal is to develop materials of epoch-making significance. Advanced materials are among the most dynamic and promising areas of scientific research in the Guangdong-Hong Kong-Macao Greater Bay Area [GBA]. The centre, which integrates applied research, commercialisation of research results, and industrial services, is a great demonstration of UM’s capability to foster innovative industry-academia collaboration in the field of advanced materials, as well as cooperation and coordinated development among industries in the GBA.’

Green Building Materials for Macao’s Infrastructure

Cement production is an energy-intensive process that requires high temperatures, and the chemical reaction involved also produces a substantial amount of carbon dioxide. In 2021 alone, carbon emissions from the production of cement used in constructing buildings, roads, and infrastructure reached 2.9 billion tons, accounting for 7 per cent of the world’s total carbon emissions. Compared with conventional products on the market, the nano-foam concrete developed by UM has smaller air voids. This advanced material can reduce cement consumption by 10 to 40 per cent, significantly reduce carbon emissions and production costs, and improve the insulating capacity of the structure by two to three times. It can be used in lightweight wall panels, door panels, and even in large-scale cast-in-place (backfill) projects. The cast-in-place concrete solution has also been applied in several major projects in Macao and Zhuhai, such as the road connecting the fourth Macao-Taipa bridge and the Zhuhai-Macao Port Artificial Island of the Hong Kong-Zhuhai-Macao Bridge, as well as the Integrated Transport Hub at the Hengqin Port between Zhuhai and Macao. These two construction projects alone have used 60,000 cubic metres of nano-foam concrete. Compared with similar solutions available on the market, this advanced material has saved 10,000 tons of cement and reduced the corresponding carbon emissions by 9,000 tons (calculated on the basis of 0.9 tons of carbon dioxide emitted during the production of one ton of cement), thus making the construction more eco-friendly.

Eco-Friendly Materials That Help Farmland Retain Water

As global warming continues to take its toll, drought and desertification become increasingly prevalent. UM has developed an innovative super hydrogel that exhibits an exceptional water absorption capacity of more than 18,000 times its weight, setting a new world record. The super hydrogel can retain up to 40 per cent of water near plant roots, which helps prevent soil erosion. It can also be buried in the ground to retain water in farmland and deserts. The product has already entered the pilot phase. Sunscreen for plants, another product developed by UM, can be sprayed on leaves to protect crops from scorching heat and harmful ultraviolet rays, and promote photosynthesis. It is particularly useful for plants grown in high-altitude, arid, or tropical environments. The production cost of the sunscreen is 70 per cent less than that of imported products available on the market, and notably, it is more effective. With a good value proposition, the sunscreen is in pilot production.

Facilitating Energy Transition With Advanced Materials

The development of clean energy is a crucial step in the global energy transition and in the building of a ‘green Macao’. In light of this, UM has developed a catalyst that can split hydrogen from photo-/electro-catalytic water. The catalyst can maintain its stability and efficiency under high electric current, which meets the requirements of water electrolysis for the industrial production of ‘green hydrogen’. In addition, it has the advantages of low preparation cost, long service life, and an environmentally friendly production process. The catalyst has been put into mass production and is being pilot tested for large-scale hydrogen production in the mainland, promoting energy transition from fossil fuels.

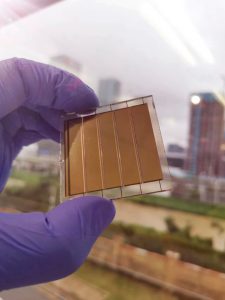

On the other hand, photovoltaic cells generally use polysilicon as a raw material, which is highly polluting, energy intensive, and costly to refine. In contrast, UM’s photovoltaic solar cells are developed using perovskite materials and can be mass-produced through low-temperature printing at low cost. It is worth noting that the university’s newly developed phase-pure quasi two-dimensional (2D) metal-halide perovskites are also made of perovskite materials, which are flexible and light in weight. The perovskites can be printed onto backpacks or clothes by aerosol spraying, providing stable and efficient solar energy storage. UM’s perovskite solar cells occupy a market-leading position in terms of photovoltaic conversion rate, and the research team is in the process of securing funding for mass production.

Pioneering Technologies for Tumour Immunotherapy

Cancer is difficult to treat because cancer cells can evade immune system attacks through immune escape. The new carbon quantum dot developed by UM can ‘facelift’ the proteins of cancer cells so that they no longer resemble normal proteins, thereby triggering the patient’s immune response against the cancer cells and eliminating them. The research team has completed the standardised production process of the carbon quantum dot material. The team has also completed planning for a GMP (Good Manufacturing Practice of Medical Products) laboratory for the production of the material. The laboratory will be located in the Traditional Chinese Medicine Science and Technology Industrial Park of Cooperation between Guangdong and Macao in collaboration with Sinopharm, a Chinese state-owned enterprise.

Supporting the High-Tech Industries

Through the centre, UM’s advanced materials projects have established connections with local and foreign businesses and social capital. This facilitates the commercialisation of research results and supports future major construction projects and the development of high-tech industries. The centre will leverage the policy advantages of the Guangdong-Macao In-depth Cooperation Zone in Hengqin, accelerate the industrialisation of research results, and help Macao develop its advanced materials industry. This will enable more UM technologies to serve the high-tech industry in the GBA and contribute to the technological strength of Macao and the country.

Text / Kelvin U

Photo / Editorial Board

English Translation / Winky Kuan

Source: UMagazine ISSUE 28